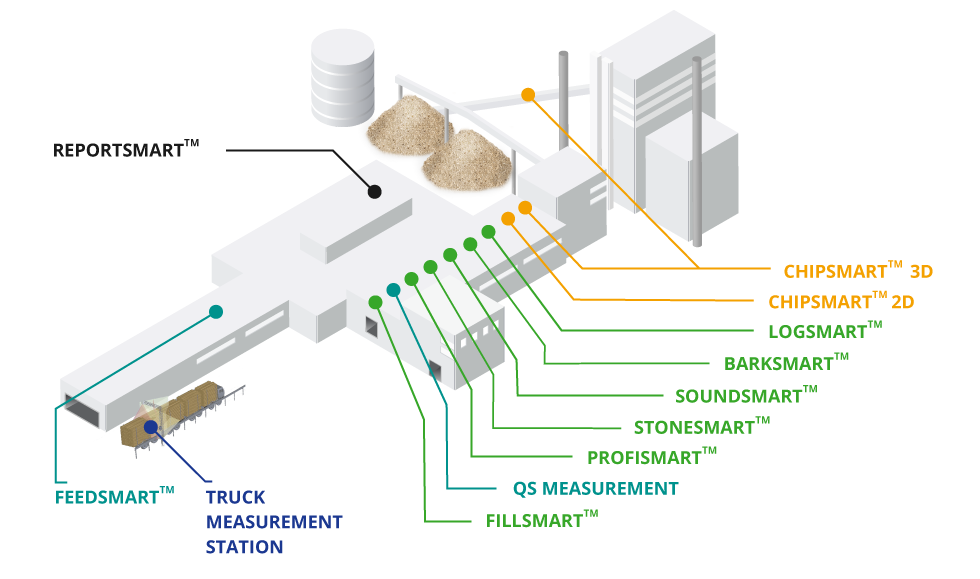

On-line measurement systems

We suggest you to obtain Teknosavo real time debarking and quality measurement devices, so your wood debarking process can be monitored and controlled precisely to produce the highest quality end-product with minimized costs.

Contact us and we can together assess, which Teknosavo’s optimization solutions for wood handling automation would provide your business the most improvement in productivity and savings.

BARKSMARTTM

BarkSmart is an optical bark measurement device which continuously measures the percentage of bark in relation to the wood surface on logs after the debarking drum. The system provides real-time analyses of the log measurement data and sends the cleanliness degree data to the control room for operators. The data can be used in debarking control so that the logs will be debarked to the desired optimum standard of cleanliness. Correct log cleanliness reduces chemical costs during pulp processing as well as wood loss in debarking. In addition, more accurate cleanliness data enables more accurate control of debarking for different seasons – significant savings can be acquired even with small reductions in use of energy, chemicals and raw material.

ProfiSmartTM

ProfiSmart is an optical measurement device that continuously measures the share of wood in relation to bark on the bark conveyor. The system provides real-time analyses of the bark measurement data for operators. The data can be used to control debarking so that unnecessary wood loss can be minimized – more accurate data enables more accurate wood quality control. ProfiSmart system consists of a camera unit and a PC unit including analysis software. The camera acquires image data from the bark flow and sends the data to the PC unit for a color analysis. The result shows the percentage of wood content in the bark flow. The bark and wood measurement data can be connected to the WoodSmart process optimization system, to the wood room automatic main control system or shown in the control room on a separate display. The system provides automatic calibration and cleaning.

FILLSMARTTM

FillSmart is an optical camera- or laser-based drum filling degree measurement system. The system provides real-time analysis of the image data and sends the drum filling degree information to the control room for operators. The data can be used in controlling the correct drum filling degree in order to minimize fiber loss in debarking process. The biggest benefit of the optical drum fill measurement is that changes in wood quality do not affect the realistic filling degree value. Fresh large-sized birch and dry softwood are typically very challenging for the traditional filling degree measurement based on weighing or hydrostatic pressure gradient measurement. With FillSmart, measurements can be calibrated according to wood species and quality.

STONESMARTTM

StoneSmart equipment consists of an acoustic sensor installed in the rotating spike roll end on the drum chipper line and a control box. The measurement result can be used directly to stop the line, or the data can be connected to a higher system. The basic solution consists of two sensors, but for demanding conditions, several sensors can be installed in the same drum chipper line. The StoneSmart stone detector system is adjusted parametrically and monitored via convenient PC program.

SOUNDSMARTTM

SoundSmart equipment consists of a sensor plate installed in the material flow and a control box. The measurement result can be used directly to control the actuator or sent to a higher system. In case the amount of material flow is large, several sensors can be installed in the same production line . The SoundSmart system is adjusted parametrically and monitored via Windows-based custom PC software.

LOGSMARTTM

The laser measuring device for logs was developed to measure wood flow on the drum chipper line. The device measures the diameter, sweep and log volume before chipping to prevent chipper chute plugs. If too much wood is simultaneously fed to the system, for example a log is too big in diameter or too crooked, or two parallel logs, the system alarms and stops the line. The alarm and measured data is sent to the debarking control system, as well as to the WoodSmart process optimization system which visualizes them on the monitor of the control room.

FEEDSMARTTM

The laser measuring device for log measurement was developed to measure wood flow on the drum infeed conveyor. The device measures the diameter, length, volume and wood level before debarking process. With precise wood material flow information, the debarking process can be optimized to the highest performance.